A well-designed industrial/heavy-duty/robust relay socket interface plays a vital role in/is essential for/forms the backbone of control panels. These interfaces provide a secure and reliable/ensure safe and consistent/guarantee dependable connection between relays and external circuits, facilitating/enabling/allowing for smooth and efficient operation. Choosing the correct interface depends on/is contingent upon/relies on factors like amperage rating, contact configuration, and environmental conditions.

- Various types of relay socket interfaces are available, including screw terminals, push-in connectors, and modular/plug-and-play/snap-in designs.

- Ensuring/Maintaining/Guaranteeing a tight connection between the interface and the relay is crucial to preventing/minimizing/avoiding electrical arcing and potential damage.

- Properly sizing/selecting/choosing the interface for the specific application is paramount/is essential/cannot be overstated.

High-Performance Relay Sockets for Automation Systems

In the dynamic realm of automation systems, performance reigns supreme. To achieve optimal operation, high-performance relay sockets play a critical position. These specialized components seamlessly bridge the gap between control circuits and high-voltage loads, enabling precise and reliable switching actions. Utilizing cutting-edge materials and architectures, high-performance relay sockets exhibit exceptional durability, longevity, and response times.

- Additionally, they offer inherent security features, safeguarding against unintended interruptions.

- As a result, automation systems incorporating high-performance relay sockets benefit from improved reliability, reduced downtime, and increased overall system productivity.

Configurable Relay Panel Design for Enhanced Control

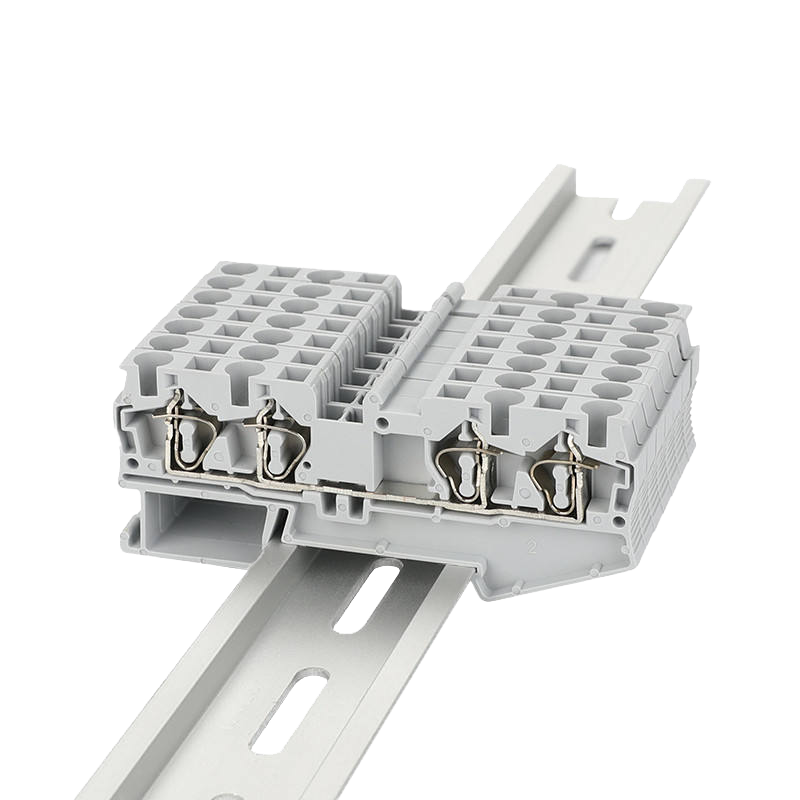

Modern industrial control often demand flexible and scalable solutions. Modular relay panel design emerges as a promising approach to meet these demands. By utilizing individual, interchangeable relay modules, system designers can assemble panels tailored to specific application requirements. This modularity facilitates easy expansion, modification, and maintenance, reducing downtime and improving overall operational efficiency.

A modular relay panel typically consists of a framework that houses multiple slots for accommodating individual relay modules. These modules can be easily installed and removed, enabling effortless customization. Furthermore, different types of relay modules are available to address a wide range of control functions, such as contact switching, time delay, and signal conditioning.

- Advantages of modular relay panel design include:

- Increased flexibility and scalability

- Minimized downtime for maintenance and upgrades

- Improved system reliability through component redundancy

- Simplified troubleshooting and diagnostics

Industrial-Grade Relay Housings

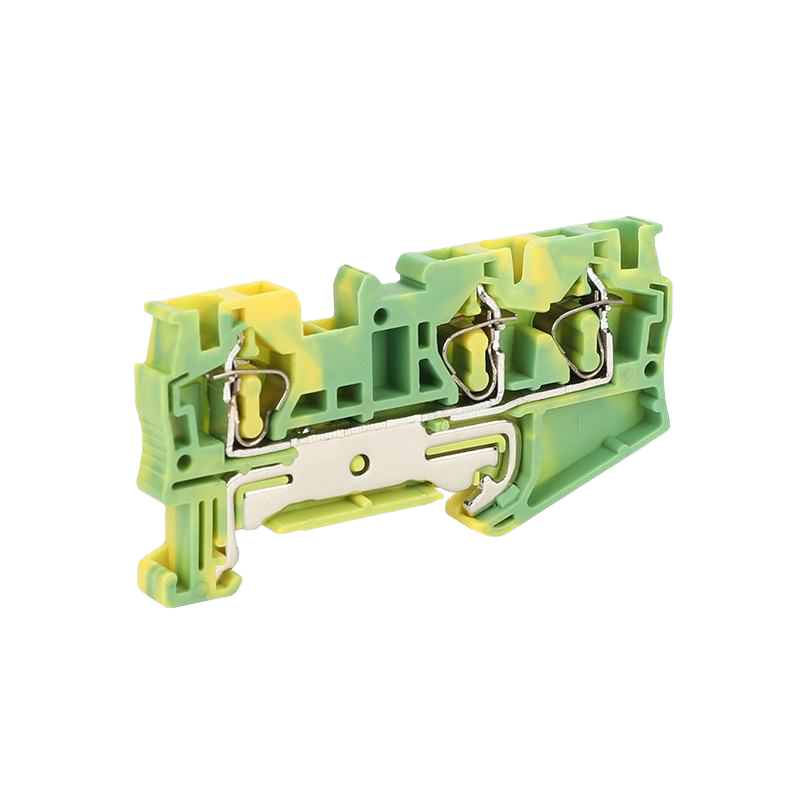

When processes demand unwavering reliability in harsh environments, choosing the right relay sockets is crucial. Ruggedized relay sockets are carefully engineered to withstand intense conditions, ensuring uninterrupted performance in applications where failure is not an option.

These sockets are fabricated from durable materials, offering increased resistance to factors such as shock, temperature fluctuations, and corrosive substances. Their design also incorporates features like shielded terminals and seals to prevent the ingress of dust, moisture, or other contaminants.

By utilizing ruggedized relay sockets, industries such as aerospace can enhance the lifespan and reliability of their electrical systems, ensuring smooth and efficient performance.

Network Control via Relay Sockets

Relay sockets represent a flexible mechanism for facilitating remote access control within networked systems. By establishing secure links between a client and a server, relay sockets enable sophisticated access control policies to be implemented. This design effectively isolates the client from directly interacting with the target system, enhancing security by minimizing potential vulnerabilities.

Additionally, relay sockets offer a scalable approach to remote access management, allowing for the smooth integration of multiple clients and diverse endpoints. A well-designed relay socket system can effectively mitigate risks associated with unauthorized access, data breaches, and malicious activity.

This approach is particularly applicable in scenarios where:

* Sensitive data requires secure transmission.

* Access control needs to be enforced across a wide-ranging network.

* Multiple users or entities require access to common resources.

By leveraging the inherent security and flexibility of relay sockets, organizations can establish robust remote access control mechanisms that safeguard their assets and ensure operational integrity.

Privated Communication Through Relay Socket Networks

Relay socket networks provide a robust mechanism for establishing secure communication channels. By utilizing a network of intermediary nodes, data can be forwarded securely between participants. Each relay node serves as a tunnel, masking the data before transmitting it to the next node in the chain. This multi-hop architecture reduces the risk of interception or eavesdropping, ensuring that sensitive information remains protected.

- Furthermore, relay socket networks can enhance resilience against network failures by providing redundant paths for data transmission.

- As a result, they are well-suited for applications that require enhanced levels of security and reliability, such as online banking.

Coordinated Relay Panels for Process Automation

In the realm of advanced process automation, robust integrated relay panels have emerged as a essential component. These panels efficiently integrate various relay types to manage diverse industrial processes. Through the use of modern technology, integrated relay panels offer improved performance, boosted efficiency, and exceptional reliability.

Their modular design allows for customizable configurations to meet the specific requirements of different industrial applications. Furthermore, integrated relay panels provide a unified platform for monitoring and managing process variables, ensuring smooth and efficient operation.

- Key advantages

- Improved efficiency

- Increased reliability

- Simplified maintenance

Stream Real-Time Data with Relay Socket Integration

In today's rapidly evolving technological landscape, access to instantaneous data is fundamental. Businesses across sectors leverage this capability to improve operations, drive strategic actions, and remain competitive to market trends. Relay Socket Integration provides a robust and scalable solution for implementing real-time data monitoring.

- Utilizing the WebSocket protocol, Relay Sockets enable bidirectional communication between applications. This supports constant information flow, ensuring that your applications are always current with the latest information.

- Advantages of Relay Socket Integration include: reduced latency, enhanced performance, and greater customer satisfaction.

- Integrating Relay Sockets allows your applications to subscribe specific data streams, enabling you to target the insights that are most critical for your operational objectives.

Instantaneous data monitoring with Relay Socket Integration empowers you to make informed decisions, fostering a more agile and knowledge-based business.

Adaptable Relay Socket Configurations for Specific Applications

In the realm of electronics and automation, exact control over electrical circuits is paramount. Relay sockets serve as crucial intermediaries, enabling remote switching and signal manipulation. To meet the diverse needs of various applications, a selection of customizable relay socket configurations are available. These configurations allow engineers to adjust the socket's specifications based on the specific demands of their project.

- Considerations influencing the choice of relay socket configuration include the voltage rating, the type of switching mechanism, and the amount of relays required.

- Furthermore, some applications may require dedicated sockets with features like shielding or integrated control circuitry.

By exploiting these customizable configurations, engineers can optimize the performance, reliability, and effectiveness of their electronic systems.

Intelligent Relay Control Panel Solutions

Today's industrial landscape demands reliable and efficient control systems. Smart relay control panels offer a cutting-edge solution to manage complex electrical circuits with precision and ease. These panels leverage integrated microprocessors and sophisticated software algorithms to monitor, analyze, and regulate power distribution across various applications. With features like real-time data logging, remote monitoring capabilities, and customizable automation sequences, smart relay control panels optimize operational efficiency while minimizing downtime and maintenance costs. By seamlessly integrating with existing infrastructure and providing a user-friendly interface, these panels empower operators to make informed decisions and maintain optimal performance across their facilities.

- Deploy smart relay control panels for improved productivity.

- Experience real-time data monitoring and analysis for proactive maintenance.

- Automate complex electrical processes with customizable automation sequences.

Enhanced Reliability with Redundant Relay Sockets

In mission-critical environments, downtime can be catastrophic. To mitigate this risk, redundant relay sockets offer a robust solution for ensuring uninterrupted operation. These sockets allow for multiple pathways for electrical signals to flow, so if one socket malfunctions, the system can seamlessly switch to the other, preventing any disruption of service.

Failure Detection and Diagnostics Through Relay Socket Feedback

In industrial settings, timely detection and troubleshooting of faults within relay sockets is crucial for ensuring smooth workflows. Relay sockets, integral components in various electrical networks, are susceptible to a range of malfunctions that can impact overall system performance. To address this requirement, sophisticated monitoring techniques are employed. One such method involves harnessing feedback from the relay socket itself through dedicated connections. By analyzing the characteristics transmitted by the relay socket, intelligent algorithms can identify potential faults with a high degree of accuracy. This proactive approach allows for preemptive intervention, minimizing downtime and ensuring optimal system performance.

High-Speed Relay Switching for Critical Control Loops

In many industrial processes, swift and precise control is paramount. High-speed relay switching plays a crucial role in these critical control loops, ensuring rapid response times to fluctuations and/or system parameters. These relays are designed for the purpose of minimizing switching delays, often on the order of milliseconds or even microseconds. This rapid actuation is essential for maintaining stability and optimizing/enhancing/improving process performance in applications such as power generation, chemical processing.

The inherent speed of mechanical relays can be enhanced through careful circuit design and the use of specialized contacts. Additionally, solid-state relays offer another option by eliminating mechanical wear and tear, providing even faster switching speeds. The selection of appropriate relay technology depends on the specific requirements of the control loop, considering factors such as switching frequency, load current, and environmental conditions.

Effective implementation involves not only selecting suitable relays but also ensuring proper communication with the control system.

Reliable cabling and low-impedance connections are critical for minimizing signal degradation and maintaining consistent performance. Ultimately, high-speed relay switching is an indispensable element in achieving precise control and optimal operation in a wide range of industrial processes.

Enhanced Power Distribution via Relay Socket Networks

In the realm of modern power grid management, implementing optimized power distribution strategies is paramount. Relay socket networks have emerged as a promising solution for achieving this goal. relay socket These networks support a decentralized and flexible structure that allows for dynamic power allocation based on real-time needs. By leveraging sophisticated relay sockets, power can be efficiently routed throughout the network, optimizing energy losses and improving overall grid stability.

- Furthermore, relay socket networks offer enhanced resilience against disruptions. The distributed nature of the system mitigates the impact of localized faults, ensuring continuous power provision to critical loads.

- Furthermore, these networks enable seamless integration with renewable energy sources, enabling a more sustainable and efficient power grid.

DSP with Relay Socket Interfaces

Relay socket interfaces provide a robust method for connecting electronic signal processing circuits to a computer system. These interfaces facilitate the transmission of continuous signals between the DSP algorithm and external devices. Utilizing relay socket interfaces in DSP systems offers benefits such as increased customizability, improved noise immunity, and the ability to interface with a broad spectrum of devices.

- Applications of DSP systems utilizing relay socket interfaces include

- industrial automation

- data transmission

- medical equipment

- audio processing and recording

Programmable Logic Controller Interface with Relay Sockets

Programmable Logic Controllers (PLCs) are heavy-duty devices widely used in automation. These controllers process logic based on input signals and provide output signals to control devices. Relay socket connectivity provides a flexible interface for connecting PLCs to external circuits.

Relay sockets allow for the interfacing of various actuators to the PLC. They act as intermediary switches, controlled by the PLC's output signals, which in turn trigger the connected devices.

This interface enables PLCs to effectively control complex industrial processes.

Fieldbus Communication Integration with Relay Panels

Integration of fieldbus communication protocols with relay panels provides a robust and scalable solution for industrial automation systems. By leveraging digital fieldbuses like Profibus, Modbus, or EtherNet/IP, data exchange between relays and control devices can be achieved efficiently. This allows for centralized monitoring, regulation of relay operations, and enhanced diagnostics capabilities. Implementing fieldbus communication in relay panels facilitates the transition towards smarter manufacturing environments.

Controlling HMIs with Relay Sockets

A effective Human Machine Interface (HMI) relies on seamless communication between the operator and the controlled system. Relay sockets provide a proven method for establishing this interface. These electrical components act as intermediary nodes, enabling digital signals from the HMI to activate external equipment.

Relay sockets offer several strengths in HMI control applications. They are known for their longevity, capable of withstanding challenging industrial environments. Their adaptability allows them to handle a wide range of voltage and current requirements. Moreover, relay sockets provide protection, safeguarding the sensitive HMI components from potential issues caused by fluctuations in the controlled system.

Cutting-edge Alarm Systems Utilizing Relay Socket Networks

Modern security systems are increasingly utilizing relay socket networks to create robust and versatile alarm platforms. These networks support real-time communication between various modules, allowing for comprehensive threat detection and swift response. By leveraging centralized relay sockets, these systems can track multiple areas simultaneously, providing detailed coverage. Furthermore, the use of relay socket networks allows for flexible system design, enabling seamless integration with diverse security applications.

- Boosted situational awareness through real-time data transmission

- Efficient response times for prompt threat mitigation

- Adaptable system configuration to meet specific security requirements

Advanced Relay Panels for Modern Factories

The current industrial revolution, also known as Industry 4.0, is transforming the manufacturing landscape. To stay competitive, factories are increasingly incorporating smart technologies. A crucial component of this transformation is the use of cutting-edge relay panels designed specifically for Industry 4.0 environments. These panels offer a range of features that enable seamless integration with traditional systems and new smart technologies.

- Essential benefits of Industry 4.0 ready relay panels include:

- Enhanced efficiency and productivity through optimization

- Instantaneous monitoring and control of processes

- Insights collection and analysis for better performance

- Seamless integration with industrial automation systems

By adopting Industry 4.0 ready relay panels, factories can achieve a substantial leap forward in their efficiency, paving the way for a more connected future of manufacturing.